About

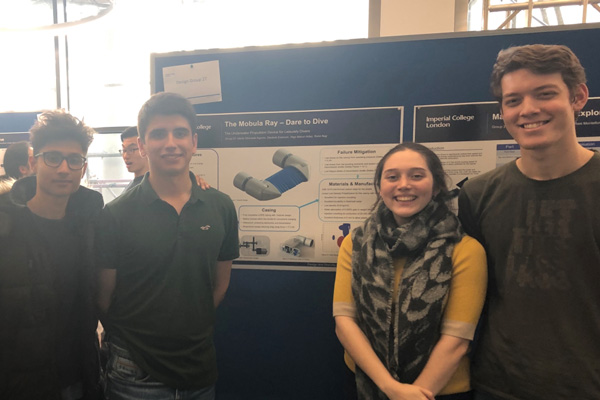

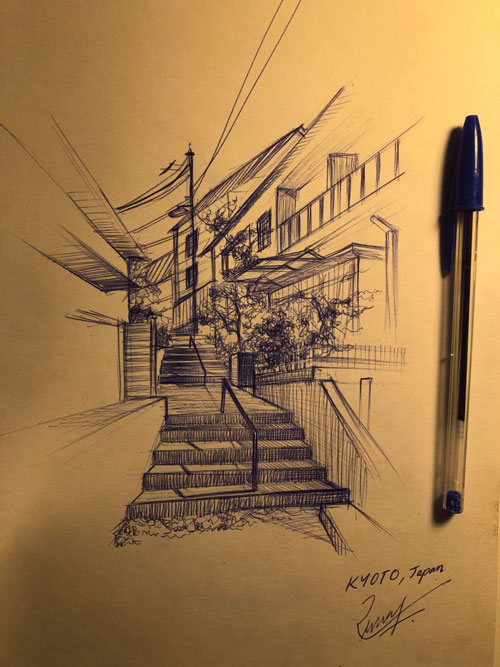

I am currently an undergraduate student studying Mechanical Engineering at Imperial College London. While I'm Indian, I can't really say that I feel like I'm from anywhere in particular. I'm lucky to have grown up in Oman, Libya, Brunei and Qatar, all of which I consider home. Have fun exploring the map below to find the countries I've lived in and the ones I've visited.

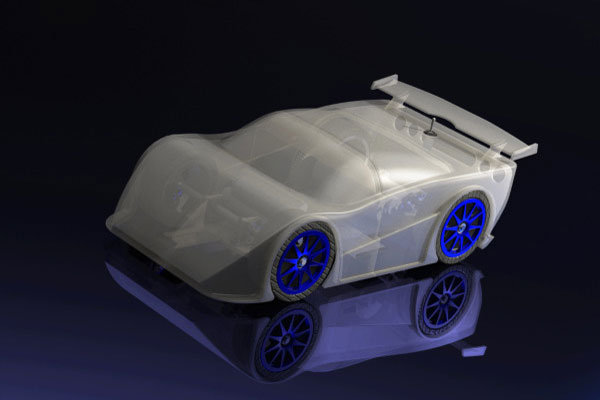

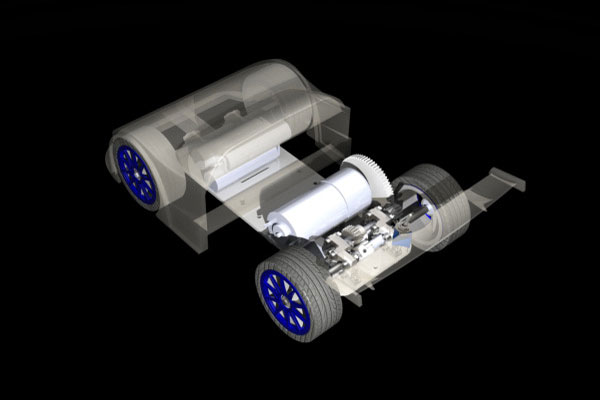

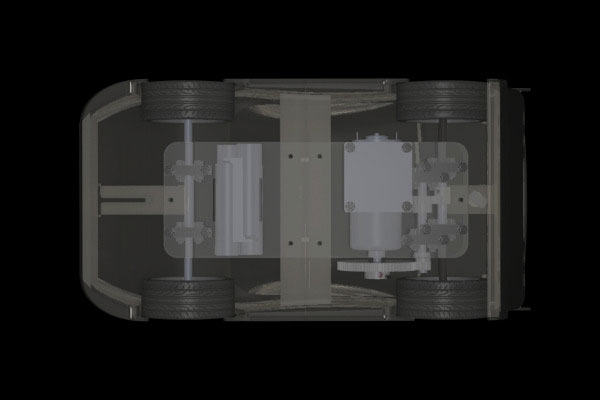

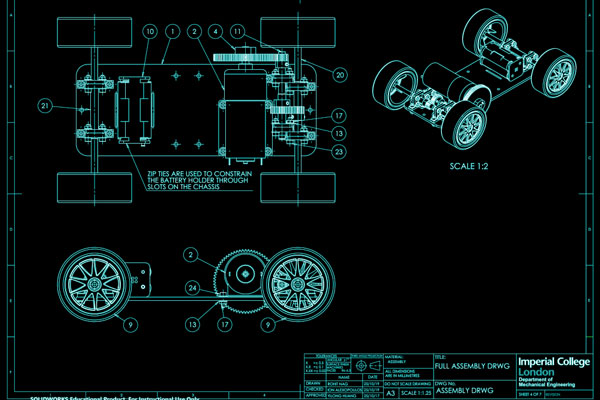

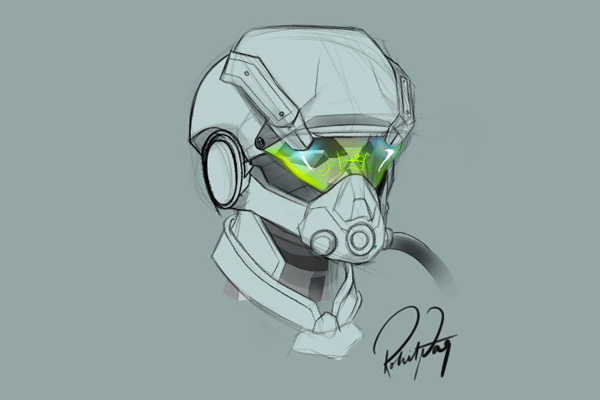

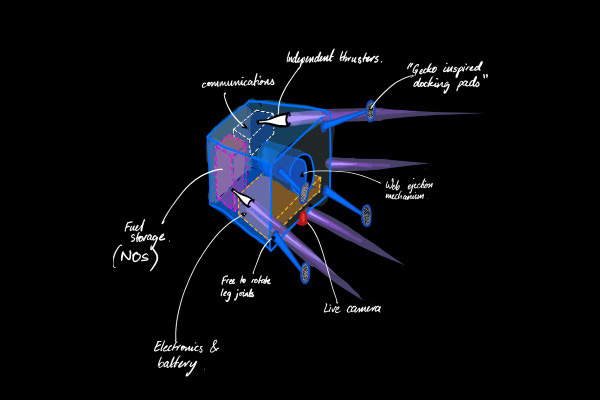

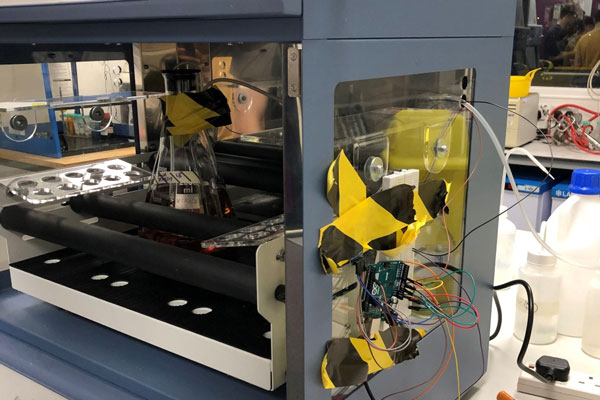

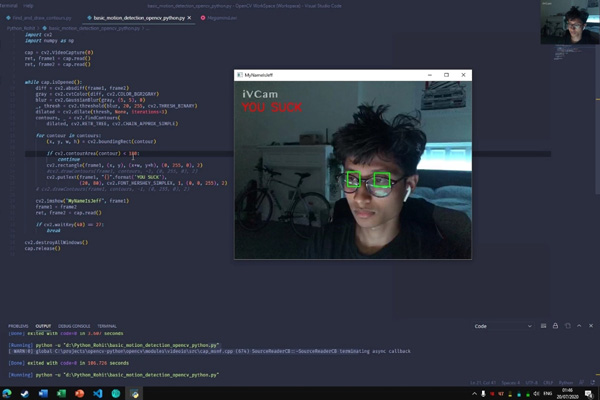

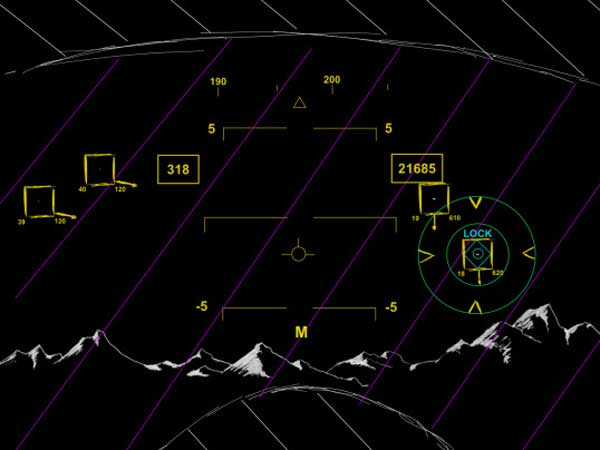

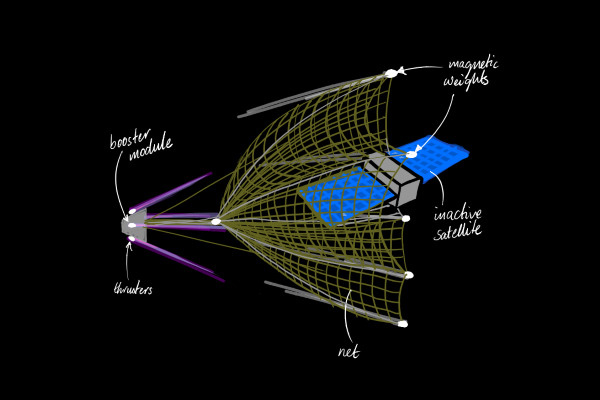

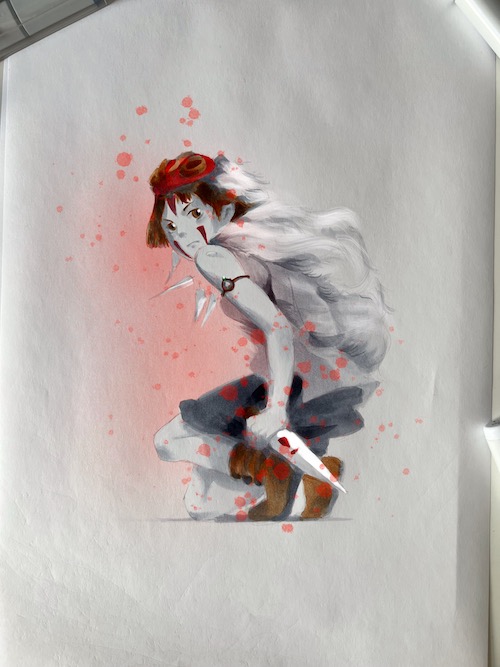

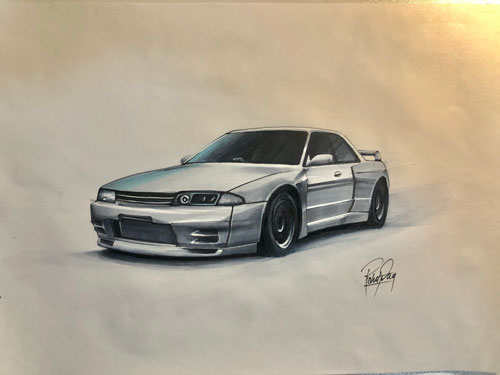

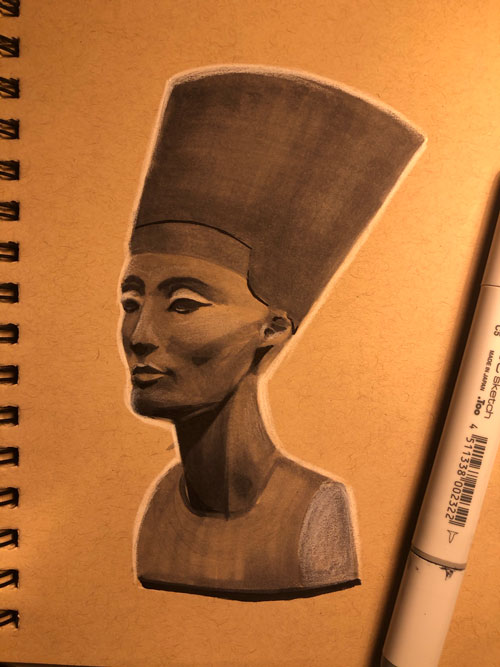

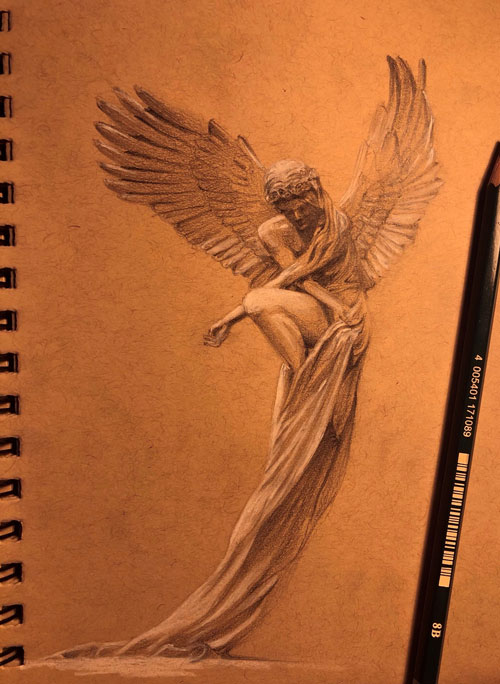

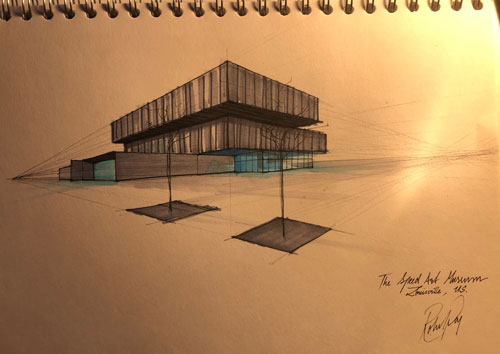

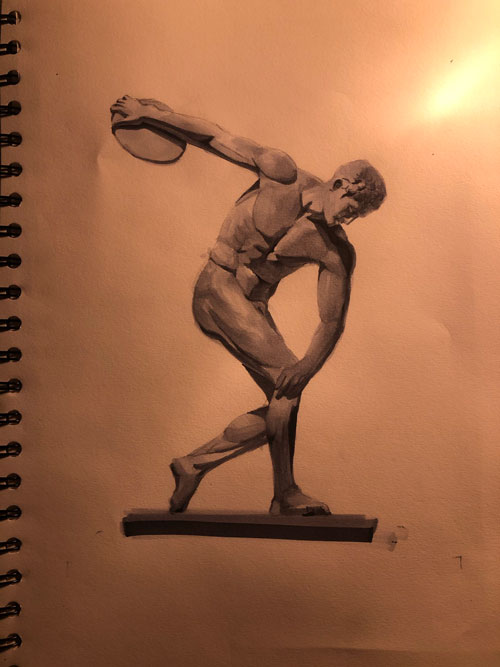

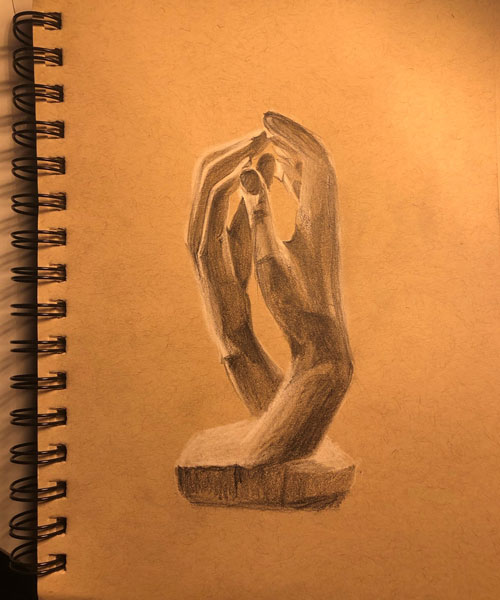

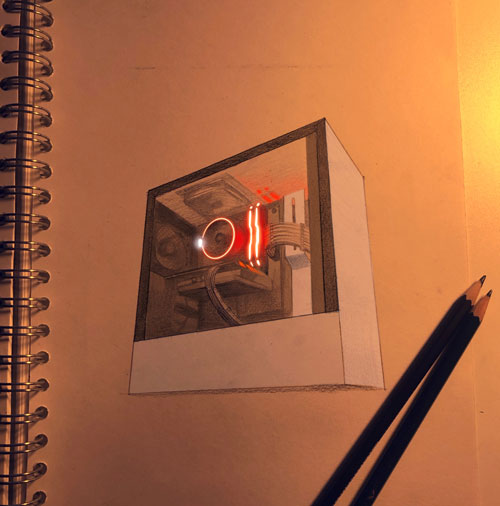

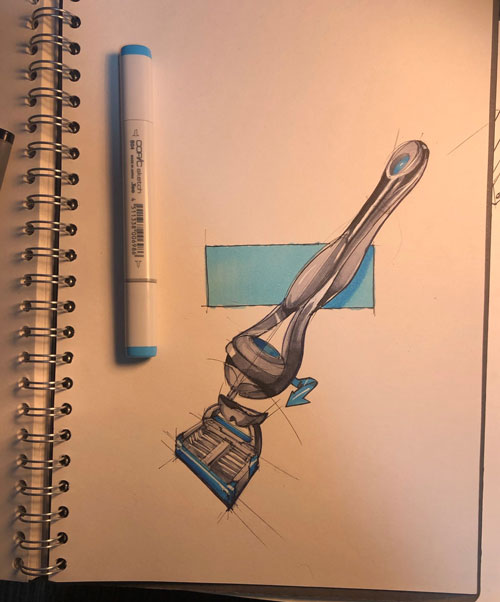

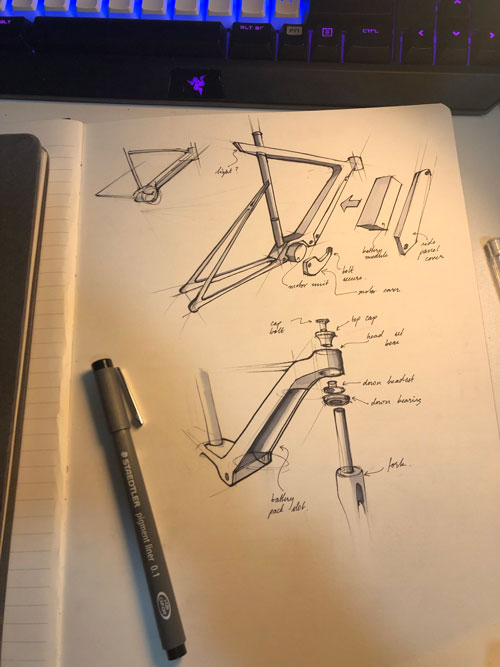

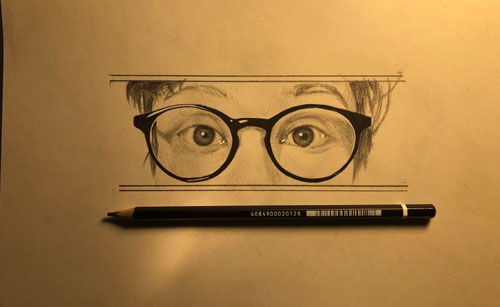

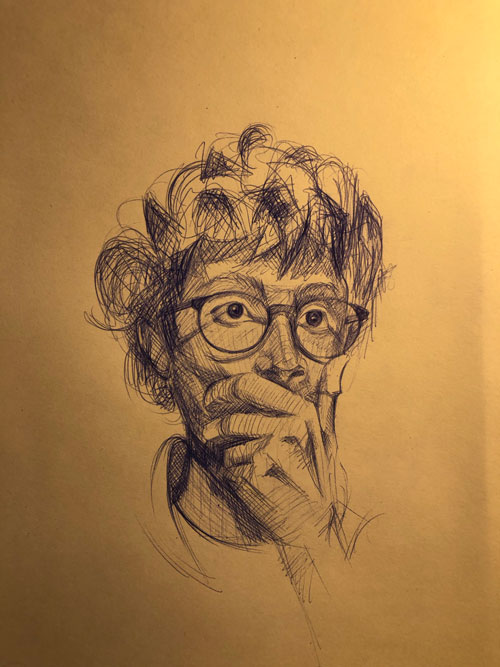

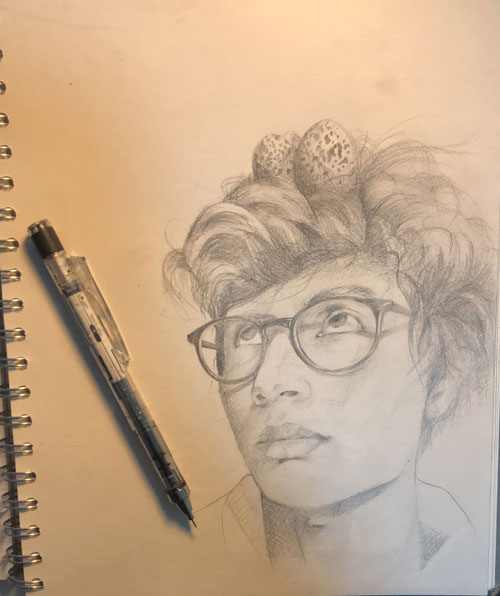

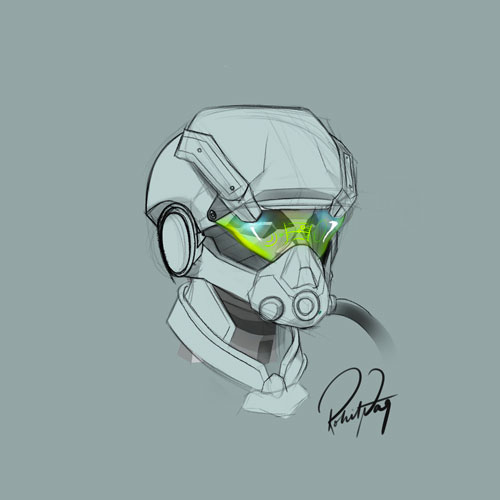

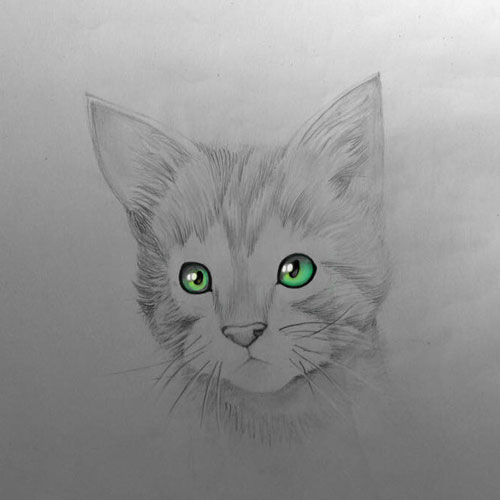

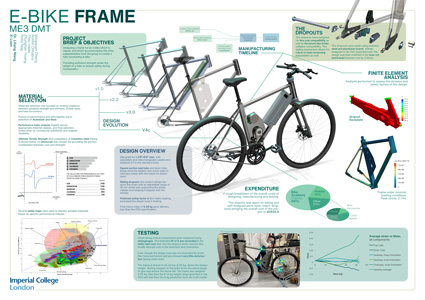

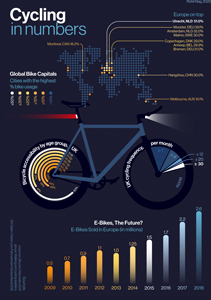

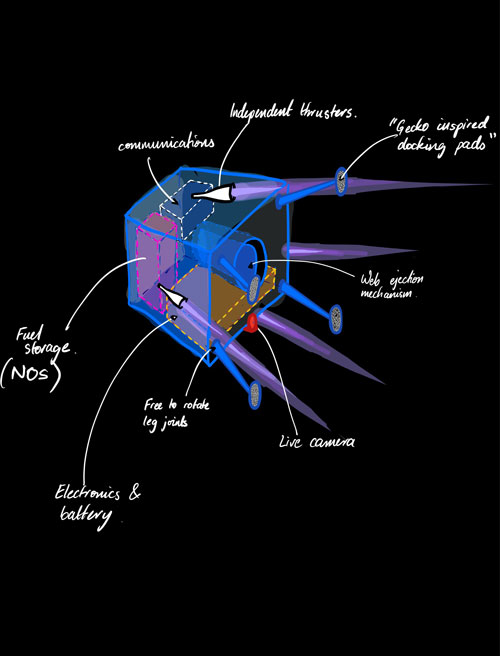

I made this website as an expanded 'resume', mainly to highlight some of my experiences, skills and the interesting projects that I have been involved with, both course-related and personal. Aside from these, I also like to spend my spare time playing tennis, cooking and drawing, some of which you can find here.

Note: This website is brand new (not any more) and there may be a few errors and twitches. I'm working on fixing these and I'll try updating the page with new information. Any suggestions would be highly appreciated and please feel free to drop me a message using the contact section at the bottom of this page.